THE PROJECT

-

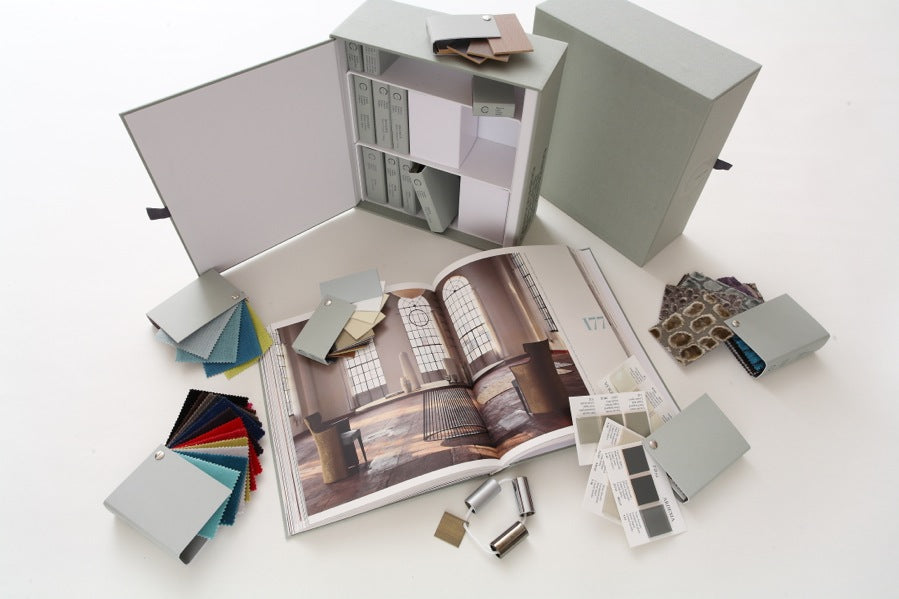

The Colli Casa project is a journey between fashion and design, it is a series of stories of lifestyles and emotions, it is a truly authentically Made in Italy system for the living area.

The 6 collections, each with a very specific personality, are designed so that they can live not only from their lines but also from materials, finishes and colours.

Indeed, it is precisely by ranging between materials, finishes and colors that the collections come to life.

As in a fashion show , chairs, tables and containers are dressed and take on a natural, playful, colourful, elegant appearance each time, allowing for great aesthetic variety and compositional freedom.

Colli Casa, through the multiple stylistic possibilities, offers the opportunity for absolutely personalized housing programs that can be developed in ever-changing and unique contexts.Colli Casa is constant design research oriented towards quality that lasts over time.

PRODUCTION

-

The production cycle begins with the careful choice of raw materials , purchased directly to guarantee certainty of quality right from start up.

As regards the wood sector, the sawmill is ISO 9001 certified and the wood is identified with the FSC and PFSC brands.

The trunks, coming from forests managed correctly and responsibly according to rigorous environmental, social and economic standards, are sawn into planks and then dried in special ovens until they reach

a maximum humidity rate of 6% which makes the wood very stable.

The subsequent processing on the essences, relating to the seats, tables and containers, is mainly carried out on numerically controlled work centers although finished manually by expert carpenters where particular sensitivity beyond mechanical precision is required.

The metal processing center, ISO 14001 certified, has a license to use the trademarks with the aim of providing customers with compliance with international standards.Furthermore, it is based on maximum versatility of production which allows us to obtain products whose careful workmanship achieves results of high aesthetic value thanks to the mastery of expert hands.

The use of laser cutting , with latest generation CAD/CAM instrumentation, guarantees maximum executive precision to support the human hand.

The 13 colors of lacquers in the Colli Casa range come to life in the painting section , which uses reliable and precise robots to obtain the nuances of natural colors or the liveliness of strong colours.

The burnished brass and the various shiny and satin chromes, including the refined carbon finish, are made in the metal treatment section.

In both departments, particular attention is paid to the environmental impact and the limitation of VOC emissions.

One of the last phases of the production cycle is upholstery , real ateliers where expert hands cut, sew and upholster our seats.

Meters and meters of splendid fabrics thus become the soul of creative productivity.

Are you a company?

A special discount is reserved for you on all Colli Casa products! Contact us for further information.

Do you need samples?

Collicasa sends you the samples you need, contact us for further information.